Combination of Mechanical engineering projects

Aero Design Project – Oregon State University

Instructor: Dr. Nancy Squires (NASA-affiliated)

Focus: Fundamentals of aerodynamics, stability, and control

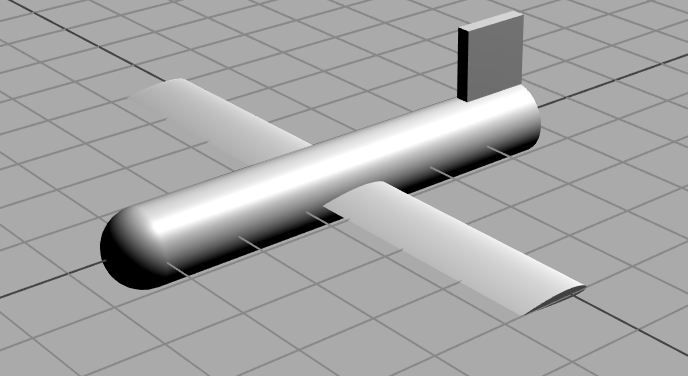

Outcome: A scale model aircraft concept featuring a mid-mounted wing, streamlined fuselage, and optimized tail fin for directional stability

Skills Gained:

CAD modeling and aerodynamic analysis

Balancing lift, drag, and structural requirements

Collaborative teamwork and iterative design processes

Through this project, I strengthened my ability to merge theory with hands-on engineering, make data-driven design decisions, and adapt quickly—skills that continue to guide my mechanical engineering career.

ME 250: Hole Puncher Project

In this introductory manufacturing and design course, I designed, prototyped, and built a mechanical hole puncher from scratch. I used a CNC milling machine for precision drilling, a manual lathe for shaping metal rods, and various bench tools (e.g., drill press, band saw) for additional fabrication. Working hands-on with these machines—selecting materials, calibrating for exact tolerances, and troubleshooting design flaws—was incredibly rewarding. This project sparked my passion for manufacturing and showed me how theoretical engineering concepts translate into tangible, real-world products.

Mechanical Systems Design ME382

HW 4 Draft of Nutcracker I drew

In this project, our team designed and built a cost-effective, remote-controlled robot—constrained to a 50×50×50 cm bounding box and under $200 in materials—to tackle five tasks:

Sprint: Travel 5 m in a straight line and return as quickly as possible.

Climb: Ascend and descend a set of three 5 cm steps.

Throw: Launch a Ping-Pong ball for maximum distance and accuracy.

Hit: Kick a Ping-Pong ball from the ground as far as possible.

Pick Up: Move 5 m to retrieve the ball, then return to the start.

Through this hands-on challenge, we strengthened our creative and critical thinking skills, integrating mechanical design (chassis, propulsion, and lifting mechanisms) with electrical circuitry (motors, remote-control receivers) to execute each task reliably. We also gained practical experience in time and cost management, ensuring the robot met project deadlines without exceeding the budget.

Overall, this project was an invaluable introduction to robotics, demonstrating how mechanical, electrical, and control systems come together to solve real engineering problems—a foundation that continues to guide our work in industry and research.

Below Is final Project:

Senior Year: Design Capstone Project

For this project, our team developed a robotic drawer system featuring interchangeable handles and integrated sensors to meet stakeholder needs. We began by collecting and analyzing data to inform our design proposal and final report, ensuring a clear understanding of the project requirements. Through Design for Manufacturing (DFM) and Design for Assembly (DFA) principles, we built a working prototype—confirming it met both design specifications and stakeholder expectations. This experience reinforced the importance of robot-oriented design, meticulous documentation, and collaborative problem-solving in mechanical engineering.